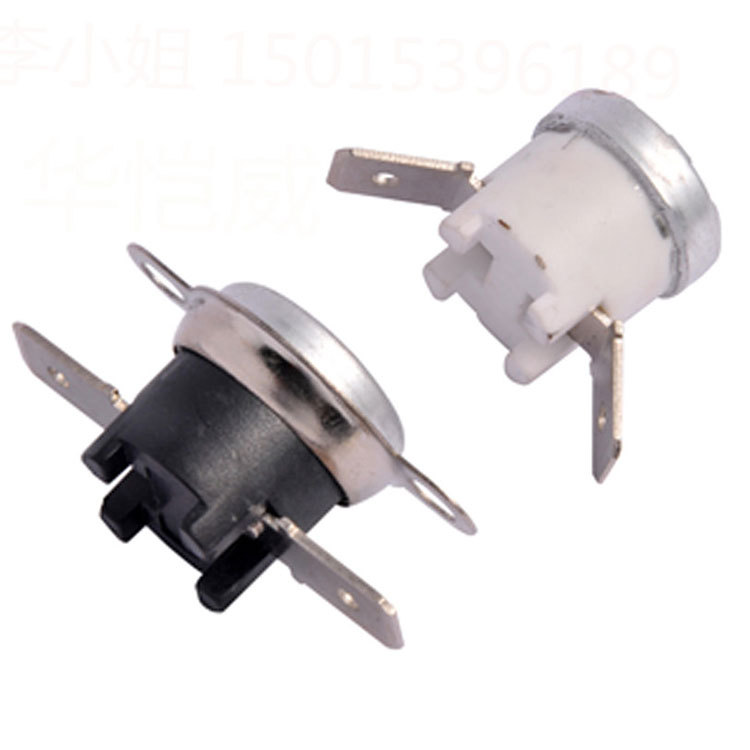

美容美发器材TM22突跳式温控器KSD301温度控制开关

更新时间:2019-09-16 14:45:22 信息编号:6851646 发布者IP:14.112.213.147 浏览:51次

- 供应商

- 惠州市华恺威电子科技有限公司 商铺

- 认证

- 资质核验:已通过营业执照认证入驻顺企:第6年主体名称:惠州市华恺威电子科技有限公司组织机构代码:441322000156980

- 报价

- 人民币¥.70元每

- 品牌

- 华恺威

- 寿命

- 100000

- 型号

- TM22 KSD301

- 关键词

- 突跳式温控器,TM22 KSD301,温度控制开关

- 所在地

- 博罗县石湾镇明月二路26号

- 手机号

- 15015396189

- 联系人

- 李小姐 请说明来自顺企网,优惠更多

- 让卖家联系我

产品详细介绍

1.基本信息 Basic Information

1.1执行标准 According to (Standard)

GB/T14536.1-2008:《家用和类似用途电自动控制器 第1部分:通用要求》

IEC 730-1:1994 Automatic electrols for household and similar

use. Part 1:General requirements

GB/T14536.10-2008:《家用和类似用途电自动控制器 温度敏感控制器的特殊要求》

IEC 730-2-9-1992:Automatic electrical controls for household

and similar use Particuar

requirements for temperature sensing controls

JB/T 3751-1997:《家用和类似用途双金属温度控制器》

JB/T 3751-1997:Bi-meral temperature controls for household

and similar use

1.2构造Structure

1.2.1. 分类 Classification

属于温度固定的双金属碟片瞬动式温度控制器。

They are temperature-fixed bi-metal Snap-Action temperature

controller

1.2.2.接地方式 Method Of Earth

通过温控器金属外盖与设备接地金属部件相连。

By means of the metal cup of thermostat connected in the

earthing meral part.

1.2.3.外观及尺寸Appearance

外观应加工良好,无有损于性能及商品价值的伤、裂、变形、毛刺、污渍等缺陷。

The appearance should be processed well, without any defect

effecting the performance or

value of the merchandise such as

strain,crach,rust,distortion,besmirch,ete.

1.3动作方式Action Forms

■ 室温下触点接通(nc),温度上升触点断开,温度降低触点恢复接通。

Normal close:Cut out at temperature rise,cut in at

temperature decreasing.

□室温下触点接通(nc),温度下降触点断开,温度上升触点恢复接通。

Normal close:Cut out at temperature decreasing,cut in at

temperature rise.

□室温下触点断开(no),温度上升触点接通,温度降低触点恢复断开。

Normal open:Cut in at temperature rise,cut out at temperature

decreasing.

□室温下触点断开(no), 温度下降触点接通,温度上升触点恢复断开。

Normal open:Cut in at temperature decreasing,cut out at

temperature rise.

□室温下触点接通(nc),温度上升触点断开,温度降低手动复位接通。

Normal close:Cut out at temperature rise,manual reset at

temperature decreasing.

1.4.型号命名方式Nomenclature of Type

TM 22 130 A 5 20 10A 1 R 4 D

Ⅰ Ⅱ Ⅲ Ⅳ Ⅴ Ⅵ Ⅶ Ⅷ Ⅸ Ⅹ Ⅺ

Ⅰ.工厂品牌(TM缩写)Factoy Brand(TM Abbreviation)

Ⅱ.工厂设计代号:(本厂为22等)Design Code:22

Ⅲ.动作温度:OFF及ON温度中的较高值Operating tempersture,the higher

value

of OFF temp.and ON temp

Ⅳ.动作温度特性:Temperature Characteristics

A-常闭型:断开温度高于接通温度

A-Normal type:OFF temperature higher than ON

temperature

K-常开型:断开温度低于接通温度

K-K type:ON temperature higher htan OFF

temperature

M-手动复位型:温控器在常温下接通,断开后,不能自动复位,需要手动进行复位

M-Manual reset type:The thermostat switches on at room

temperature and it won be able

to reset after switching off

O-一次动作性:温控器在室温下接通,温控器断开后,不能复位

O-One-shot type:The thermostat switches on at room

temperature and it wont be able to

Reset switching off

Ⅴ.标称动作温度误差值:Open temperature difference

2表示Said±2℃

3表示Said±3℃

5表示Said±5℃

10表示Said±10℃

Ⅵ.动作温度与复位温度差值,2位Open temperature or Rstet temperature the

difference

手动复位型无此项数字 The non-manual reset

Ⅶ.额定阻性负载电流:10A,15A,16A Current Rating:5A,10A,15A

Ⅷ.端子姿态Terminal Angle

1:水平Horizontal

2:垂直Vertical

3:垂直/45°Vertical/45°

4:水平/45°Horizontal/45°

5:45°/45°

6:水平/垂直Horizontal/Vertical

7:其它类型角度

3/

Ⅸ.端子类型Temrinal Type

N:187系列端子(4.8×0.5)187Series

M:187系列端子(4.8×0.8)187Series

R:250系列端子(6.3×0.8)250Series

F:非标端子Not Criterion

Ⅹ.固定形式Holder Type

1:活动固定器Free Holder

2:无固定器 Without the Holder

3:45°固定器45°Holder

4:90°固定器90°Holder

5:180°固定器180°Holder

Ⅺ.绝缘壳体Insul ating Material

D:电木Free Holder

E:陶瓷Without the Holder

P:PPS

2.主要性能Primary Performance

2.1.动作温度Operating Temperature

2.1.1.温度特性Characteristic

断电温度: 130±5℃

接通温度: 标准复位

2.1.2. 测试方法Test method

把温控器夹在测试区内,等待测温区的温度平衡后,开始测试。测试炉内以空气作为加热

介质,在测温区放置温度计或温度传感器。在温度进入动作温度公差范围前2K开始,以小于1K/min的温度变化速率进行加温或降温,其间必须进行搅拌,使温度分布充分均匀;测温区温

度分布均匀性在±0.4K以内。

测试装置可设置通断显示装置。温控器两接线端子间电压大于5V,通过试样电流大于10mA。

4/

2.2 绝缘电阻 Insulation Resistance

用DC500V绝缘电阻表加额定电压DC500V测定大于100MΩ。

With a DC500V megger, borne DC 500V,the tested value is over

100 MΩ.

2.3 电气强度Dielectric Strength

带电金属部件与非带金属部件之间能承受接近正弦波的1500V50Hz交流电压历时一分钟的耐压试验,不击穿,无闪络。

Parts between elecriferous components and non-electriferous

ones can bear 1500V 50Hz AC current,

Which is nearly sine wave, for one minute as bearing

test,Resulted no breakdown,no flashover.

2.4.长期工作Zui高环境温度Max.Ambient temperature

□100℃ □140℃ ■185℃ □205℃ □220℃ □245℃ □280℃ □320℃

3.可靠性测试 Reliability Test

3.1.试验条件Test Conditions

◆ 环境温度20±5℃;

◆ 环境相对湿度60%~70%;

◆ 电源应为额定电压及额定频率50Hz、60Hz的正弦波电源。

在试验结果不发生异议的情况下,按下述条件试验亦可:

◆ 环境温度5~35℃;

◆ 环境相对湿度45%~85%;

◆ 电源为接近正弦波的交流电;

◆ Ambient temperature: 20℃

◆ Ambient Relative Humidity: 60%~70%;

◆ The power supply should be of sine wave,with rated volts

and rated frequency of50Hz、60Hz;

Without discrepancing the result,test may be implemented

according to the following conditions;

◆ Ambient temperature varies berween 5~35℃;

◆ Ambient relative humidity varies berween45%~85%;

◆ The power supply should be AC nearly sine wave;

3.2工作寿命Working Life

将温控器试样接上额定电压,Zui大工作电流(偏差±5%),对温控器给以升、降温进行触头开闭试验,Zui大频率6次/min,闭合时间1秒以上。每天闭一次作为一个周期,记录周期数,不发生因电弧引起的极间短路及对带电件短路,然后检查性能。样品进行周期为10万次的耐久性试验后应符合下列性能指标:

◆ 动作温度对试验初始值的变化在100℃以下为±5℃,在100℃以上为±5%;

◆ 绝缘电阻100 MΩ以上(用DC500V绝缘电阻表加额定电压DC500V测定);

◆ 带电金属部件与非带电金属部件之间能承受接近正弦波的1500V

50Hz交流电压历时一分钟的耐压试验,不击穿,无闪络;

◆ 机能上无性损伤,手动复位温控器的复位操作无异常。

5/ Powered the sample thermostats with rated volts and

max.current(windage: 5%),increase and decrease

the temperature to test Opening/Closning of the thermostat’s

contacts.The max frequency should be 6

times/min,contact keep closed for one second.Ecery opening

and closing is calculated as one circle,make

record of circles.And no short circuit was found.Then check

the performance.After tested 100,000circles,

the samples accord with the following guideline of

specifications:

◆Initial value of experiment caused by action

temperature:

< 100℃: ±5℃;≥100℃: ±5%;

◆Insulation resistance over 100MΩmore than (tested by DC500V

megger,powering with

DC500V);

◆ Parts between electriferous components and

non-electriferous ones can bear 1500V 50Hz

AC current,which is nearly sine wave,for one minute as

bearing test.Resulted no breakdown,no flashover;

◆No permanent mechanics’damage.No abnormity od reset

operation for manual reset

Thershover;

3.3 耐低温、高温和冷热冲击

Resistance of low Temperature & High

Temperature,Cold&heat Strike

将温控器试样放置在-20℃的恒温箱中,在温度稳定后保持1h,取出放置2h;然后将试样放置在150℃的恒温箱中,在温度稳定后保持1h,取出放置2h;Zui后,将试样放置在-20±3℃的恒温箱中

0.5h,取出试样放置在室温环境2~3min,再取出在150±3℃的恒温箱中0.5h,取出放置在室温环境2~3min作为一个周期,连续进行5个周期。在整个试验过程中,被测试样品表面不得出现疑露或水滴。完成后,样品应符合下列性能指标:

◆ 动作温度对试验初始值的变化在100℃以下为±3℃,在100℃以上为±3%;

◆ 绝缘电阻100MΩ以上(用DC500V绝缘电阻表加额定电压DC500V测定);

◆ 带电金属部件与非带电金属部件之间能承受接近正弦波的1500V 50Hz交流电压历时一分钟

的耐压试验,不击穿,无闪络;

Sample thermostats are placed in the constant-temperature box

with the temperature of -20℃.When

temperature inside levels off, keep it for 1h.Than take the

samples out and place for 2h,And ten place

Them in the constant-temperature box with the temperatuer of

150℃,keep for 1h after temperature,

lecels off, and take out and place for 2h.Finally,keep the

samples in the constant-temperature box of -20

±3℃ for 0.5h,then take out and place then in room

temperature.(2~3min as oen circle,and for 5 circles

In a row.)During the experiment,no coagulation or drips is

ever found on the surface of the asmples. When experiment

finished,samples should accod with the following guideline of

specifications:

◆Initial value of experiment caused by action

temperature:

< 100℃: ±3℃;≥100℃: ±3%;

◆Insulation resistance over 100MΩmore than (tested by DC500V

megger,powering with

DC500V);

◆ Parts between electriferous components and

non-electriferous ones can bear 1500V 50Hz

AC current,which is nearly sine wave,for one minute as

bearing test.Resulted no breakdown,no flashover;

6/

3.4. 耐潮湿 Dampness Resistance

将温控器试样按GB2423.3规定放入温度40±2℃、相对湿度的恒温箱内48h后,

样品应符合下列性能指标:

◆ 动作温度对试验初始值的变化在100℃以下为±3℃,在100℃以上为±3%;

◆ 绝缘电阻100MΩ以上(用DC500V绝缘电阻表加额定电压DC500V测定);

◆ 带电金属部件与非带电金属部件之间能承受接近正弦波的1500V 50Hz交流电压历时

一分钟的耐压试验,不击穿,无闪络;

Samples thermostat are sealed in the instrument(constant

temperature&constant humidity),detailed

as temperature of 40±2℃ relative humidity of 90%~95%,as per

regulations ofGB2423.3.A fter placed

for 48h,the samples should accord with the following

guideline of specifications:

◆ Initial value of experiment caused by action

temperature:

< 100℃: ±3℃;≥100℃: ±3%;

◆ Insulation resistance over 100MΩmore than (tested by DC500V

megger,powering with

DC500V);

◆ Parts between electriferous components and

non-electriferous ones can bear 1500V

50HzAC current,which is nearly sine wave,for one minute as

bearing test.Resulted no breakdown,no flashover;

3.5. 耐振动 Vibration Resistance

把温控器试样固定在有充分强度的板上,对上下、前后、左右各方向,以频率20~25Hz振幅3

mm来回时间5min,历时各1h。完成后,样品应符合下列性能指标:

◆ 动作温度对试验初始值的变化在100℃以下为±3℃,在100℃以上为±3%;

◆ 绝缘电阻100MΩ以上(用DC500V绝缘电阻表加额定电压DC500V测定);

◆ 带电金属部件与非带电金属部件之间能承受接近正弦波的1500V 50Hz交流电压历时

一分钟的耐压试验,不击穿,无闪络;

Sample thermostats are fixed on the surface of board with

full intension,Then vibrate the samples with frequency

20~25Hz,swing3mm,come-and-go time 5mm,in dierctions of

fluctuation,front-back,

left-tight,for 1h,After tested,the samples should accord with

the following guideline of specifications:

◆ Initial value of experiment caused by action

temperature:

< 100℃: ±3℃;≥100℃: ±3%;

◆ Insulation resistance over 100MΩmore than (tested by DC500V

megger,powering with

DC500V);

◆ Parts between electriferous components and

non-electriferous ones can bear 1500V

50HzAC current,which is nearly sine wave,for one minute as

bearing test.Resulted no breakdown,no flashover;

3.6. 耐跌落 Falling Resistance

温控器试样从200mm高自由跌落在水泥地、石板或钢板等坚固的水平面上,分别作上、下、

左、右、前、后各落下一次。完成后,样品应符合下列性能指标: 7/

◆ 动作温度对试验初始值的变化在100℃以下为±3℃,在100℃以上为±3%;

◆ 绝缘电阻100MΩ以上(用DC500V绝缘电阻表加额定电压DC500V测定);

◆ 带电金属部件与非带电金属部件之间能承受接近正弦波的1500V 50Hz交流电压历时

一分钟的耐压试验,不击穿,无闪络;

源头厂家直销电吹风暖风机恒温热敏开关定制热保护器17AM+PTC0.70元/

源头厂家直销电吹风暖风机恒温热敏开关定制热保护器17AM+PTC0.70元/

品牌:华恺威 厂家直销HKW电源变压器可恢复温度保险丝KSD9700恒温开关质量保证0.46元/

厂家直销HKW电源变压器可恢复温度保险丝KSD9700恒温开关质量保证0.46元/

额定电流电压:5A250V 厂家直销温度开关过热保护器免费送样温控开关限温器认证齐全CCC0.45元/

厂家直销温度开关过热保护器免费送样温控开关限温器认证齐全CCC0.45元/

品牌:华恺威 控制板电路可恢复温度保险丝金属膜熔断器厂家定做AUPO温度保险丝0.30元/

控制板电路可恢复温度保险丝金属膜熔断器厂家定做AUPO温度保险丝0.30元/

品牌:华恺威 厂家直销定制陶瓷外壳温控高温温度控开关KSD BW9700质量保证UL0.58元/

厂家直销定制陶瓷外壳温控高温温度控开关KSD BW9700质量保证UL0.58元/

品牌:华恺威 源头厂家直销定制设制空调热保护器JUC-31F量大价优温度保护器温控开关0.65元/

源头厂家直销定制设制空调热保护器JUC-31F量大价优温度保护器温控开关0.65元/

品牌:华恺威 ST01 SAFTTY热保护器电机马达绕组温控开关非德国Thermik特密克0.80元/

ST01 SAFTTY热保护器电机马达绕组温控开关非德国Thermik特密克0.80元/

触点形式:常闭 源头厂家直销定制设计豆浆机敞开式温控开关ccs9100恒温器CCC0.53元/

源头厂家直销定制设计豆浆机敞开式温控开关ccs9100恒温器CCC0.53元/

电流:250